- How to barcode your products

-

- Food date and lot marking solutions for small businesses 0

- Changing the ink cartridge in your REINER 940 0

- Planning to open your own microbrewery? 0

- Why millennials decide to shun plastic in favour of eco-friendly materials 2

- 5 common misconceptions about handheld inkjet printers 0

- REINER introduces the new P1-MP6 ink for dark surfaces 0

- How to barcode your products 4

- Choosing the right ink for your REINER printer 0

How to barcode your products

Barcodes are essentially ways by which information can be encoded in a visual pattern which is readable by a machine. They are located in different areas of packages for different industries. In general, they help to store information concerning products, on the product or packaging.

Working with a barcode makes it easier and faster to access information compared to entering it in a system manually.

Barcodes have the ability to stash away a large amount of data in a limited space. This is done with either no error or the littlest of errors.

TYPES OF BARCODES

There are currently two major types of barcodes under which there are several other types. Some of these are mentioned below. This range of barcodes makes it easier to determine the type of barcode that is most suitable for your products.

It is also important to note that there are different variations of barcodes for different industries and the barcode that will increase your business value and boost the efficiency of your enterprise is different from that which will do the same for another enterprise.

The two major types of barcodes are:

- One-Dimensional (1D) Barcode

- Two-Dimensional (2D) Barcode

ONE-DIMENSIONAL (1D) BARCODES

One-Dimensional (1D) Barcode is used to represent data systematically by making use of spacing and width for the parallel lines in the barcode. This type of barcode includes some of the most recognised and traditional types of barcodes, examples of which are the UPC and the EAN codes.

UPC Barcodes

These are used in the labeling of consumer goods at points at which they are sold around the world especially in the United States and in countries such as the United Kingdom, New Zealand, and Australia among others. There are essentially two different variations of the UPC codes: the UPC-A variation and the UPC-E variation.

The UPC-A variation is used to encode twelve numerical digits and the UPC-E variation, which is a smaller variant, is used to encode only six numerical digits.

EAN Barcodes

These barcodes are used to label consumer goods around the world for scanning at points-of-sale, especially in countries within Europe. The EAN Barcodes look very similar to the UPC Barcodes. The main difference between these two barcodes is the geographical location which they are applied to. There are five different variations of this barcode with EAN-13 barcode being the default form factor. The EAN-13 variation is used to encode thirteen numerical digits. While another variant, EAN-8 barcode is used to encode eight numerical digits on products that have very limited space, an example of which are small candies.

Other variations are: EAN-18, EAN-8, JAN-13, ISBN, and ISSN.

Code 39 Barcodes

Also known as Code 3 or 9 Barcodes.

These barcodes are used to label goods produced by several industries and are usually found in the United States Department of Defense and the automotive industry. This type of barcode permits the use of not only digits but also characters. The name of the barcode comes from its ability to encode 39 characters (this was in its early days), while the most recent version has increased the character set to 43. This barcode is similar to the Code 128 barcode although it is not as compact. It has no variation.

Code 128 Barcodes

Code 128 Barcodes are essentially compact codes with high density that are made use of in some industries such as logistics and transportation for ordering and distribution. These barcodes have been designed for non-POS products an example of which is when the applications for supply chains label their units with Serial Shipping Container Codes (SSCC). Code 128 Barcodes are used for sorting highly diversified information as a result of their ability to support any character present in the character set of ASCII 128.

Code 93 Barcodes

Code 93 Barcodes are used in the section of logistics to label electronic components, identify the packages present in retail inventory and provide additional information concerning delivery for the Canadian Post. With similarity to Code 39, Code 93 barcodes come with complete ASCII support. Code 93 barcodes have additional security embedded within the code itself. They are also about 25% shorter than the barcodes produced in Code 39 as a result of the high density of the barcodes and their compact sizes.

Codabar Barcodes

Codabar Barcodes are used by FedEx, healthcare outfits (such as the United States blood banks), photo labs, libraries, and logistics. The primary benefit of this type of barcode is its ability to print easily and be produced by any impact style printer. This type of barcode makes it possible for users to produce several Codabar Barcodes while making use of consecutive numbers even without the use of a computer. Codabar Barcodes are a discrete and self-checking symbology that is able to encode up to 16 different characters and an extra 4 start/stop characters.

Other variations: Codeabar, Rationalize Codabar, USD-4, ANSI/AIM BC3-1995, Code 2 of 7, Ames Code, NW-7 Monarch.

GS1 DataBar

GS1 DataBar Barcodes were previously known as Reduced Space Symbology.

These barcodes are employed by retail outlets to help identify products and perishables, consumer coupons and other small objects in the healthcare industry. GS1 DataBar is essentially more compact than the typical consumer-facing barcodes. This barcode was introduced to the system in 2001. It has since become the industry standard for retail coupons in the United States.

Other variations: GS1 DataBar Omnidirectional, Expanded Stacked, Stacked, Stacked Omnidirectional, Expanded, Truncated, Expanded Stacked.

Other types of One-Directional (1D) Barcode include MSI PLESSEY and ITF (Interleaved 2 of 5).

TWO-DIMENSIONAL (2D) BARCODES

These symmetrically represent data that makes use of two-dimensional shapes and symbols. They are similar to the linear 1D barcode, except they can represent more information per unit area.

QR Code

These codes are often used in tracking and marketing, such as business cards, magazines, and advertisements. They feature fast readability, flexibility in size and offer high fault tolerance. These codes support four modes of data: kanji, byte/binary, numeric and alphanumeric and are free to use.

Data Matrix Code

These codes are employed in labeling small objects, goods, and documents. Their tiny prints make them suitable for small products in logistics and operations. The U. S. Electronic Industries Alliance (EIA) provides that the QR codes be used to label small electronic components. These codes are similar to QR codes as they feature fast readability and high fault tolerance.

Other variations: Micro-Datamatrix.

AZTEC Codes

AZTEC Codes are often used in the transportation industry, especially for airplane boarding passes and tickets. They can be decoded even with poor resolution and this makes them useful when tickets are presented on a phone or printed poorly. They also take up less space as they do not require a blank “quiet zone” in their surroundings.

Other types of 2-D barcodes are PDF417 Codes.

BARCODE PLACEMENT

In order to ensure that the barcode is scanned correctly and placed on the product properly and efficiently, it is essential to adhere to the following guidelines:

- Barcode creation

- Selecting colors

- Placement on packaging

- Selecting the barcode size.

1. Barcode creation

The quality of the barcode is essential for a successful scan. It is important that you use high-resolution artwork and high-resolution printing so that the lines and spaces are clean and readable. If the barcodes are not clean and readable, it will become difficult to scan them which may lead to loss of sales and market shares.

2. Selecting colours

The best colour combination to use for a barcode is one with black bars and white background (spaces and quiet zones). There are, however, other combinations for colors. Before you can use these combinations there are guidelines which you must follow some of which are:

- Avoid printing the bars in red or reddish colours.

- Ensure you print the bars in a single ink colour

- Print on a red background

- Avoid printing the symbol background and much more

3. Placement on packaging

The location of the barcode on your package can affect the ability of the scanner to access the barcode.

For packages signed at checkout, the barcode should be in the lower right-hand section at the back of the package. Make sure to avoid the edge of the package and ensure the white surface around the barcode is enough in order to ensure a clean scan. The printed surface should also be smooth in order to avoid interference with the scanner.

4. Selecting the barcode size

The size of the barcode on the package will depend on the location of the package and the manner with which the barcode is printed. It is imperative that the barcodes are printed at their full height, without the removal of any portion in order to make it fit on the package which would result in incorrect scanning. If you desire to resize the barcode, ensure that you do not resize by enlarging or shrinking it. However, recreate it in the size you desire.

PRINTERS

Several printers are employed in producing barcodes. To determine the kind of printer to use for printing your barcodes, the following needs to be noted:

- The type of environment the barcode labels will be exposed to

- The intended lifespan of the barcode labels

- The barcode application the labels will be used for

There are essentially three types of printers that are appropriate for barcode printing, they are:

- InkJet printers

- Direct thermal printers

- Thermal transfer printers

InkJet printers

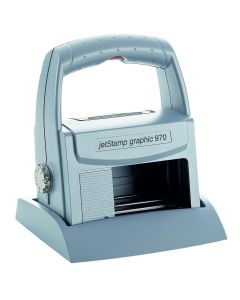

These printers make use of high-speed printing for both small and large mark sizes and they provide optimum print resolution. They are is ideal for printing high quality on corrugated boxes and other porous and non-porous materials. Some of them are handheld. An example is the REINER inkJet 970 Graphic.

- They save cost by consuming less ink

- They provide the convenience of branding and on-demand coding

Direct thermal printers

These printers make use of labels that are sensitive to heat and blackens whenever they are passed under a print head. They do not require the use of ribbons. Their application is for purposes with a short span, such as shipping. These printers are sensitive to the environment and they are not fit for environments with exposure to heat, abrasion or sunlight.

- These printers produce less waste

- They are durable and reliable and but the cost of maintaining them can be quite high

Thermal transfer printers

These printers make use of a small ribbon that melts onto the label when it is passed under the print head to create the image. These barcodes are durable, and they can withstand abrasion, heat, and moisture.

- They are more expensive then InkJet printers

- They can print in various kinds of stock

REINER INKJET 970 GRAPHIC

To learn more about the REINER inkjet 970 Graphic handheld printer, and its barcoding capabilities, visit the product page below.

-

REINER P3-S Standard Ink Cartridge (porous surfaces) - Fits 940 and 970 Graphic

£110.21View DetailsIncl. VAT

£110.21View DetailsIncl. VAT

Despatched in 1-2 working days. -

REINER P3-MP4 Super Quick Drying Ink Cartridge (glass) - Fits 940 and 970 Graphic

£188.34View DetailsIncl. VAT

£188.34View DetailsIncl. VAT

Despatched in 1-2 working days. -

REINER P3-MP3 Quick Drying Ink Cartridge (metal & plastic) - Fits 940 and 970 Graphic

£148.21View DetailsIncl. VAT

£148.21View DetailsIncl. VAT

Despatched in 1-2 working days.